|

|

There

is a right way

and at least a

half dozen wrong

ways to hand fabricate

and install a copper

roof. Seams are

important! Joints

are important!

Asthetic value

- important. Long

life - important!

The correct installation

is ... you guessed

it ... important!

|

|

|

Copper

drip edge is

handmade and

essential to

proper water

shedding.

|

|

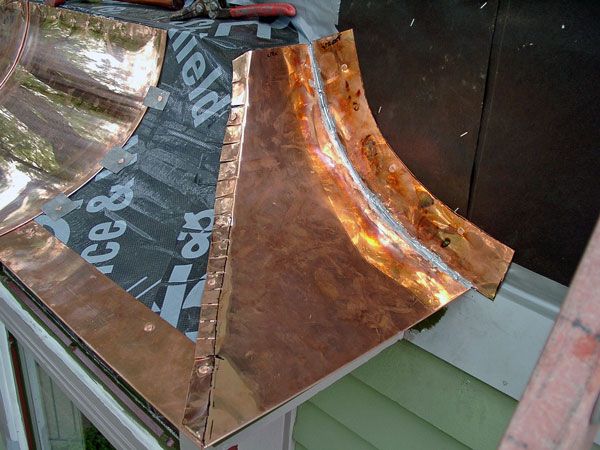

All

running seams

are hand rolled

and pressed -

by the book -

no leaks here!

|

|

Corners,

trim and other

joints are all

hand soldered.

Notice the use

of copper nails

to secure the

roof to the structure.

You don't want

to mix metals

here due to oxidation

occuring between

different metals. We

also use heavy

duty "ice

and water shield" underlayment

which guarantees

there will be

no leaks as a

result of the

typical ice/water

dams we get up

here in the north

country.

|

|

|

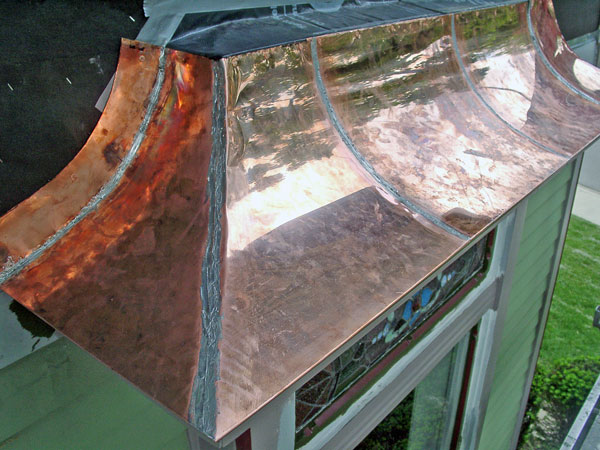

The

roof cap is handmade

in our shop under

controlled conditions.

Precision, with

finesse is the name of the game here.

You can't rush this type of work.

|

|

|

John

is fussy and

takes a lot of

pride in doing

the job right

- and making

it look good!

Notice how smooth and sharp the corners

and edges are.

|

|

|

|

In

using modern

technology to

facilitate old

world techniques

John's skills

in hand soldering

lead into the

seams not only

makes them water

tight, but his

natural artistic

skills allow

for the clean

lines of the

Mansard Window

Cap to show.

|